Scraper

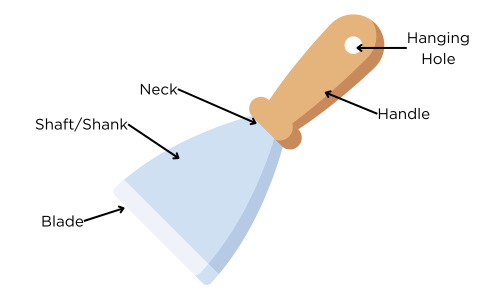

Anatomy of a Scraper

What is a Scraper?

Who would use a Scraper?

Scrapers are widely used by:

- Woodworkers and Carpenters: For smoothing wood surfaces, removing glue, and refining joints to achieve a clean finish on furniture, cabinetry, and joinery.

- Metalworkers and Fabricators: To remove rust, burrs, and mill scale from metal surfaces, ensuring they are clean and ready for welding, painting, or further machining.

- Painters and Decorators: For scraping off old paint, varnish, or wallpaper, helping to prepare surfaces for fresh coats and preventing imperfections.

- 3D Printing Enthusiasts: For removing prints from the build plate, cleaning up rough edges, and ensuring a smooth surface finish on printed parts.

- DIY Hobbyists: For home projects that involve removing old finishes, adhesives, or leveling surfaces before refinishing or repainting.

- Automotive Technicians: To clean surfaces, remove gasket material, and prepare parts for assembly in engine work and other repairs.

- Flooring Installers: For removing adhesives, tile residue, and underlayment from floors, ensuring a clean surface for new flooring installation.

- Model Makers: To refine small parts, remove burrs, and smooth surfaces on detailed projects, from architectural models to miniatures.

- Artists and Sculptors: For scraping, smoothing, or removing layers in various media, such as clay, plaster, or metal, to achieve precise textures and finishes.

Safety Precautions with Scraper Tools

Here are some key safety precautions when using scraper tools:

- Wear Protective Gear: Always use safety glasses to shield your eyes from debris and gloves to protect your hands, especially when using metal or sharp-edge scrapers.

- Use the Correct Angle: Keep the scraper at the recommended angle (usually 10-15 degrees) to prevent slipping, which could cause injury or damage the surface.

- Keep Blades Sharp: A dull blade requires more force and increases the chance of slipping. Regularly sharpen or replace scraper blades for safer, more efficient use.

- Apply Controlled Pressure: Avoid excessive force to prevent the scraper from digging too deep or slipping. Use firm, controlled strokes.

- Clear the Work Area: Make sure your workspace is free of clutter and distractions to maintain focus and prevent accidents.

- Dispose of Old Blades Safely: When replacing blades, use a blade disposal container to prevent accidental cuts.

- Store Properly: Keep scrapers in a designated storage space with blade guards or covers to prevent accidental contact when not in use.

- Avoid Excessive Heat: If using on metal surfaces, be cautious of heat, as scrapers can become hot and cause burns during prolonged use.

Following these precautions ensures safer handling of scraper tools and helps prevent injuries while maintaining efficiency on the job.

Considerations in Choice of Scraper

Here are some key considerations when choosing a scraper:

- Type of Material: Choose a scraper made of appropriate material for your project. Metal scrapers are durable and effective on tough surfaces, while plastic scrapers are gentler, ideal for surfaces that scratch easily.

- Blade Shape: Flat blades are versatile, but curved or contoured blades can better fit specific surfaces, especially in woodworking or metalworking.

- Handle Comfort and Grip: Look for ergonomic handles, especially for extended use. Non-slip grips can enhance control and reduce fatigue, especially in heavy-duty applications.

- Blade Replaceability: Scrapers with replaceable blades are more cost-effective in the long run, as you can replace worn blades without buying a new tool.

- Flexibility: Flexible blades conform better to curved or uneven surfaces, while rigid blades are ideal for tough, flat surfaces requiring force.

- Size of the Scraper: Choose a size that matches the scope of your work. Small scrapers work best for detail work, while larger scrapers cover more area for bigger projects like flooring or paint removal.

- Safety Features: Some scrapers come with blade guards or covers for safe storage, which is especially useful if you need to transport or store the tool frequently.

- Intended Use: Certain scrapers are specialized—like cabinet scrapers for woodworking or floor scrapers for adhesive removal—so match the scraper type to your specific task for the best results.

Considering these factors will help you select a scraper that’s well-suited to your needs, making tasks easier, safer, and more effective.

Frequently Asked Questions (FAQ)

1. What materials can I use a scraper on?

Scrapers can be used on a variety of materials, including wood, metal, glass, tile, plastic, and painted surfaces. Always select a scraper with the right blade material to prevent scratching or damaging sensitive surfaces.

2. How do I choose the right scraper for my project?

Consider the type of material, blade shape, and rigidity needed for your task. Flexible blades work well on uneven surfaces, while rigid blades are better for tough, flat surfaces. Ergonomic handles and replaceable blades are also beneficial for frequent use.

3. How do I keep my scraper sharp?

For metal scrapers, use a sharpening stone or file to maintain a sharp edge. Many scrapers also have replaceable blades, so you can swap out dull blades to maintain effectiveness.

4. Can I use a scraper to remove old paint?

Yes, paint scrapers are specifically designed to remove paint, varnish, and other finishes. For best results, choose a scraper with a rigid blade and apply controlled pressure to avoid gouging the surface underneath.

5. Are scrapers safe to use on glass?

Yes, there are specific scrapers designed for glass that feature softer blades or plastic edges to avoid scratching. Always check the blade material and apply gentle pressure when using scrapers on glass.

6. How do I safely dispose of used scraper blades?

Store used blades in a designated disposal container or wrap them in sturdy tape to avoid accidental cuts. Many hardware stores have safe disposal programs for used blades.

7. What’s the difference between a cabinet scraper and a paint scraper?

A cabinet scraper is typically a thin, flexible piece of metal used in woodworking for a smooth, finished surface, while a paint scraper is a rigid tool used to strip paint or varnish. Each serves a distinct purpose and is best suited for its intended task.

8. Can I use a scraper in 3D printing?

Yes, scrapers are commonly used to remove prints from the build plate, clean up edges, and achieve a smooth finish on printed parts.

9. Do scrapers need any special maintenance?

Clean scrapers after each use, particularly if they’ve been exposed to glue, paint, or adhesives. If you have a metal scraper, sharpen the blade periodically, and always store scrapers with blade guards or in a safe place.

10. What’s the best grip for using a scraper?

Hold the scraper with a firm, controlled grip at a shallow angle (10-15 degrees) to the surface. Apply even pressure and avoid excessive force to prevent slipping or gouging the material.

ToolFinder Recommends

For General Purpose Applications

5Pcs Putty Knife, Set, 1" 2" 3" 4" 5" Scraper, Spackle Knife, Paint Scraper, Scraper Tool, No Rusting, Perfect For Repairing Drywall, Removing Wallpaper, Mud, Plaster Scraping

For general purpose applications – it’s best to have a collection of a few widths of scraper to make sure you can get where you need to, this set can fit that bill: 5Pcs Putty Knife, Set, 1″ 2″ 3″ 4″ 5″ Scraper, Spackle Knife, Paint Scraper, Scraper Tool, No Rusting, Perfect For Repairing Drywall, Removing Wallpaper, Mud, Plaster Scraping

6 Pack Putty Knife, Flexible Plastic Paint Scraper Tool for Spackling,Plastic Putty Knife, Putty Knife Set, Plastic Spreader, Spackle Tool, Plastic Putty Knife Scraper, Scraper Tool, Putty Scraper

Have a need for some plastic scrapers? These are best when you’re worried about harm to the base material while scraping. This set would give some variability at a low cost: 6 Pack Putty Knife, Flexible Plastic Paint Scraper Tool for Spackling,Plastic Putty Knife, Putty Knife Set, Plastic Spreader, Spackle Tool, Plastic Putty Knife Scraper, Scraper Tool, Putty Scraper

For 3D Printing Applications

5 Pcs 3D Printer Scraper 3D Printer Accessories 3D Printer Removal Tool Kit Scraper Stainless Steel Enhanced Version Knife with Sturdy Wooden Handle for Easy Separation of Prints

Removing a print from a 3D Print bed can be quick and easy or require a little help. This set of scrapers can give the leverage needed to pry that print as needed: 5 Pcs 3D Printer Scraper 3D Printer Accessories 3D Printer Removal Tool Kit Scraper Stainless Steel Enhanced Version Knife with Sturdy Wooden Handle for Easy Separation of Prints