Bar Clamps (Light/Medium Duty)

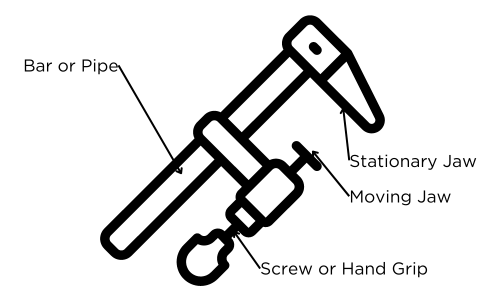

Anatomy of a Bar Clamp

What is a Bar Clamp?

Who would use a Bar Clamp?

Bar clamps are widely used by:

1. Woodworkers and Carpenters: For holding pieces of wood together while glue sets, or for securing workpieces during cutting, sanding, or finishing.

2. Metalworkers and Welders: To clamp metal pieces together before welding or drilling.

3. Cabinet Makers and Furniture Builders: For assembling and gluing frames, cabinets, and furniture.

4. DIY Enthusiasts: For various home projects, from building shelves to repairing furniture.

5. Craftsmen and Hobbyists: In making and assembling smaller items like picture frames or wooden toys.

6. Construction Professionals: For temporary holds during framing and structural assembly.

7. Artists: Particularly those working in mixed media or large-scale installations that require assembly of various components.

8. Set Designers and Prop Makers: In theater, film, and television production for constructing and assembling sets and props.

Bar clamps are valued for their adjustability and strong, even pressure, making them essential in any setting where items need to be held firmly in place for assembly, gluing, or processing.

Safety Precautions with Bar Clamps!

When using bar clamps, consider these safety precautions to prevent accidents and ensure a safe working environment:

1. Wear Protective Gear: Depending on the task, wear safety glasses to protect your eyes from flying debris and gloves to protect your hands.

2. Inspect the Clamp: Before use, check the bar clamp for any damage or wear, especially in the jaws and the tightening mechanism. A damaged clamp might fail during use.

3. Use the Right Size and Type: Choose a clamp that is appropriate for the size and weight of the workpiece. Using a clamp that’s too small or not strong enough can lead to slippage or failure.

4. Apply Appropriate Pressure: Over-tightening can damage the clamp, the workpiece, or cause the clamp to slip. Apply enough pressure to hold the workpiece securely without deforming it.

5. Secure the Workpiece: Ensure the workpiece is stable and supported before applying the clamp to prevent it from falling and causing injury.

6. Keep Fingers Clear: When tightening or loosening the clamp, keep your fingers away from the path of the moving jaw to avoid pinching.

7. Do Not Overextend: Avoid extending the bar clamp beyond its capacity, as this can weaken the clamping pressure and stability.

8. Store Properly: When not in use, store clamps in a designated area to prevent tripping hazards and to keep them in good condition.

9. Use Clamps on Suitable Surfaces: Ensure the surfaces you are clamping are not slippery and are clean to improve grip and reduce the risk of the clamp slipping.

10. Be Mindful of Surroundings: Be aware of others working around you to prevent accidentally hitting someone with the clamp or having the clamp interfere with their work.

Following these precautions will help minimize the risk of injuries and ensure that your work with bar clamps is both safe and effective.

Considerations in Choice of Bar Clamp

When choosing a bar clamp, consider the following factors to ensure you select the right type for your needs:

- Clamping Capacity: This refers to the maximum distance between the jaws. Select a clamp that can accommodate the size of the workpieces you commonly work with.

- Throat Depth: The distance from the edge of the bar to the center of the clamping pad. A deeper throat allows clamping further from the edge of the workpiece, providing more versatility.

- Clamping Force: Different clamps offer different levels of clamping pressure. Consider the amount of force needed for your projects; delicate tasks may require less force, while heavy-duty applications may need stronger clamps.

- Bar Material and Strength: The bar’s material and design affect its durability and rigidity. Steel bars are strong and resist bending under pressure, making them suitable for heavy-duty work.

- Jaw Material and Design: Soft jaws or jaws with non-marring pads are important when working with delicate surfaces to prevent damage. For tougher jobs, durable metal jaws may be more appropriate.

- Mechanism and Ease of Use: Consider how the clamp is tightened—whether by a screw, trigger, or another method—and how easily and quickly it can be adjusted.

- Build Quality: A well-constructed clamp will have a smooth operation, resist wear over time, and maintain its accuracy and strength.

- Brand and Warranty: Reputable brands often guarantee quality and reliability. A good warranty can provide peace of mind and protection against defects.

- Price: Balance the features and quality of the clamp with your budget. While higher-priced models may offer better performance and durability, mid-range clamps might suffice for occasional use or lighter tasks.

- Additional Features: Some bar clamps come with extra features like reversible jaws for spreading, quick-release buttons for rapid adjustments, or integrated stands for stability.

Considering these factors will help you choose a bar clamp that meets your specific requirements, ensuring effective, safe, and efficient work on your projects.

ToolFinder Recommends

JORGENSEN 4-pack Steel Bar Clamps Set, 6-inch (2) & 12-inch (2) Medium Duty F-Clamp, 600 Lbs Load Limit, for Woodworking

In many occasions, it’s helpful to have a single-hand use bar clamp. With a single-use bar clamp you can generally hold/pull a piece into place while you tighten or even loosen the clamp. This set is worth looking into: Jorgensen 6″ Spreader/Bar Clamp Set, 4-pack,One-Hand Light Duty E-Z Hold Clamp/Spreader, 99216A,Black Orange

JORGENSEN 4-pack Steel Bar Clamps Set, 6-inch (2) & 12-inch (2) Medium Duty F-Clamp, 600 Lbs Load Limit, for Woodworking

Need a little more clamping force for your projects? This set isn’t usable with a single hand for most, but it’s going to provide much more clamping force for your projects that require it: JORGENSEN 4-pack Steel Bar Clamps Set, 6-inch (2) & 12-inch (2) Medium Duty F-Clamp, 600 Lbs Load Limit, for Woodworking

Strong Hand Tools UM125-C3 Regular Duty Bar Clamp, 12-1/2" Capacity, 2400 LBS Clamping Pressure, 5-1/2" Throat Depth

Need a large amount of force for your project? These would also be great for a welding or similar application. Check out the Strong Hand Tools UM125-C3 Regular Duty Bar Clamp, 12-1/2″ Capcaity, 2400 LBS Clamping Pressure, 5-1/2″ Throat Depth