CNC Router Table (Small Scale)

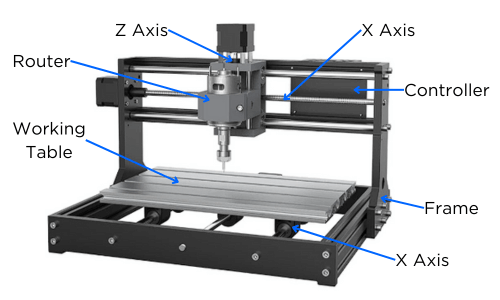

Anatomy of a CNC Router Table

What is a CNC Router Table?

Who would use a CNC Router?

What should you consider when selecting a CNC Router Table?

When selecting a CNC router table for small projects, consider these key factors:

- Size and Workspace: Assess the table size and working area to ensure it accommodates the size of projects you plan to undertake. Consider the space available in your workshop for the machine.

- Material Capability: Make sure the CNC router can handle the types of materials you want to work with, such as wood, plastics, soft metals, or composites.

- Precision and Accuracy: Look for a machine that offers the precision and accuracy needed for your projects. Check specifications like resolution and repeatability.

- Spindle Power: The spindle’s power determines the machine’s ability to cut through materials. More power means it can handle harder materials and more demanding tasks.

- Software Compatibility: Ensure the CNC router is compatible with the CAD/CAM software you intend to use for designing and translating your projects into machine instructions.

- Ease of Use: Consider user-friendly features, such as intuitive controls, easy setup, and clear instructions, especially if you’re new to CNC routing.

- Expandability and Upgrades: Check if the machine can be upgraded or expanded with additional accessories or features to grow with your skills and needs.

- Support and Community: Look for a CNC router with good manufacturer support and an active user community. This can be invaluable for troubleshooting, tips, and project ideas.

- Budget: Balance the features and capabilities you need with your budget. Keep in mind that higher-priced models may offer greater capabilities and durability.

- Safety Features: Consider safety features such as emergency stop buttons, dust collection systems, and protective enclosures to ensure a safe working environment.

Evaluating these factors will help you choose a CNC router table that meets your specific needs for small projects, offering the right balance of functionality, ease of use, and value.

Safety Precautions with CNC Routers!

ToolFinder Recommends

FoxAlien Masuter Pro CNC Router Machine

There are many options for CNC Router Tables available from many stores. For beginners looking to get started with things such as signs and labels, we recommend FoxAlien Masuter Pro CNC Router Machine, Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon Carving Cutting

FoxAlien Fixed-focus FA20W Engraver Module Class 4 450nm PWM TTL for FoxAlien Masuter 4040, Masuter Pro, XE-PRO, 4040-XE, WM-3020 CNC Engraving Machine (5000mW Optical Output)

To increase the capacity of your CNC machine to perform more tasks – consider a laser addon. FoxAlien Fixed-focus FA20W Engraver Module Class 4 450nm PWM TTL for FoxAlien Masuter 4040, Masuter Pro, XE-PRO, 4040-XE, WM-3020 CNC Engraving Machine (5000mW Optical Output)