Hammer Drill

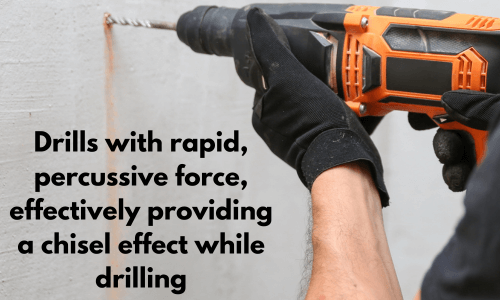

Hammer Drill Primary Feature:

What is a a Hammer Drill?

Who would use a Hammer Drill?

A hammer drill is widely used by:

- DIY Enthusiasts: For handling home improvement projects that require drilling into tough materials, such as mounting shelves on concrete walls, installing outdoor fixtures, or assembling masonry projects.

- Homeowners and Renters: Ideal for routine maintenance and upgrades, like hanging heavy items on brick or concrete walls, installing curtain rods, or anchoring fixtures outdoors.

- Masons and Bricklayers: Essential for drilling into stone, brick, or concrete to install anchors, fasteners, or perform precision masonry work.

- Electricians and Plumbers: Used for creating access points in concrete or masonry for wiring, conduits, or pipes during installations and repairs.

- Contractors and Handymen: A must-have for professionals tackling diverse tasks on job sites, such as drilling anchor holes for structural supports or heavy-duty fasteners.

- Remodelers and Renovators: Valuable for home renovations requiring durable tools to drill through concrete floors, tiled walls, or reinforced stone countertops.

- Landscapers and Outdoor Builders: Handy for installing fences, retaining walls, or outdoor structures, requiring reliable performance on hard surfaces.

- Trades Apprentices and Students: Essential for learning skills in trades like construction or masonry, providing hands-on experience with industry-standard tools.

- Hobbyists and Makers: Useful for creating durable projects involving hard materials, such as concrete sculptures, outdoor planters, or stone-based crafts.

- Furniture Makers and Assemblers: Occasionally used for drilling into reinforced furniture bases or walls during assembly or mounting tasks.

- Security Camera Installation: For mounting cameras and associated equipment boxes to masonry and other hard materials.

A hammer drill provides these users with the power, efficiency, and versatility to confidently handle tough materials, making it indispensable across trades, hobbies, and home improvement needs.

Safety Precautions with Hammer Drills

Using a hammer drill can involve risks, especially when working with tough materials like concrete or brick. Following proper safety precautions ensures you can work effectively while minimizing hazards.

1. Wear Appropriate Personal Protective Equipment (PPE):

-

Safety Goggles: Protect your eyes from dust, debris, and flying fragments.

-

Work Gloves: Reduce vibration impact and protect your hands from sharp surfaces.

-

Dust Mask or Respirator: Prevent inhalation of fine dust when drilling into concrete or masonry.

-

Ear Protection: Hammer drills can be loud; use earplugs or earmuffs to protect your hearing.

2. Inspect the Drill and Accessories:

-

Check for Damage: Inspect the hammer drill, power cord, and drill bits for any visible damage before use.

-

Secure the Bit: Ensure the drill bit is properly seated and tightened in the chuck to avoid slipping during operation.

3. Prepare the Workspace:

-

Clear the Area: Remove clutter and ensure you have enough room to work safely.

-

Check for Hazards: Use a stud finder or circuit tester to locate electrical wires, pipes, or other hidden obstacles before drilling.

-

Stabilize the Surface: Secure the material you’re working on to prevent movement during drilling.

4. Use the Right Technique:

-

Grip the Drill Firmly: Always use both hands to maintain control, utilizing the side handle if available.

-

Start Slowly: Begin drilling at a low speed to guide the bit into the material before increasing power.

-

Maintain Pressure: Apply consistent, moderate pressure—too much force can damage the bit or the material.

5. Manage Dust and Debris:

-

Use a Dust Extraction System: Many hammer drills have ports for connecting vacuum systems to control dust.

-

Clean the Area Regularly: Keep the workspace clear of accumulated dust and debris to reduce slip hazards.

6. Protect Against Vibration Injuries:

-

Limit Exposure Time: Prolonged use of hammer drills can cause hand-arm vibration syndrome (HAVS). Take regular breaks.

-

Use Anti-Vibration Features: If available, activate the tool’s vibration control settings.

7. Electrical Safety:

-

Avoid Wet Conditions: Never operate a corded hammer drill in damp or wet areas to prevent electrical shocks.

-

Use a GFCI Outlet: When working outdoors or in risky environments, plug your drill into a ground fault circuit interrupter (GFCI) outlet.

8. Be Aware of Overheating:

-

Cool the Drill Bit: If drilling for extended periods, periodically remove the bit to cool it down and prevent overheating.

-

Monitor the Tool: Allow the hammer drill to rest if the motor gets too hot.

9. Store Properly After Use:

-

Unplug and Inspect: Turn off and unplug the tool before storing it. Check for any damage that may have occurred during use.

-

Store Safely: Keep the drill and bits in a dry, secure location away from children or unauthorized users.

By following these safety precautions, you can use a hammer drill effectively and minimize risks during your projects.

Considerations in Choice of Hammer Drill

Selecting the right hammer drill depends on the nature of your projects, the materials you’ll work with, and your preferences for features and functionality. Here are the key factors to consider:

1. Power Source:

-

Corded Hammer Drills:

-

Provide consistent, high power, making them ideal for heavy-duty or prolonged tasks.

-

Require access to an electrical outlet, limiting mobility.

-

-

Cordless Hammer Drills:

-

Offer greater portability and convenience, especially for outdoor or remote work.

-

Limited by battery life; look for high-capacity lithium-ion batteries.

-

2. Power and Performance:

-

Motor Power (Amps or Voltage):

-

For corded drills, higher amps (7–10A) indicate more power for tough materials.

-

For cordless drills, choose a model with at least 18–20V for sufficient performance.

-

-

Blows Per Minute (BPM): Indicates the hammering speed; higher BPM means faster penetration into hard materials.

3. Speed and Control:

-

Variable Speed Settings:

-

Essential for adjusting the speed based on material and task.

-

-

Reverse Function:

-

Useful for removing drill bits from dense materials or driving screws.

-

4. Mode Options:

-

Drill-Only Mode: Suitable for standard drilling tasks on softer materials like wood or metal.

-

Hammer Drill Mode: Designed for masonry or concrete work.

-

Chisel Mode (if available): Found in rotary hammer drills for demolition tasks.

5. Chuck Type and Size:

-

Keyless Chuck: Allows quick and easy bit changes, convenient for light to medium-duty use.

-

SDS or SDS-Plus Chuck: Provides secure bit retention for heavy-duty applications, especially in masonry work.

-

Chuck Size: Most models feature a 1/2-inch chuck, accommodating a wide range of bit sizes.

6. Comfort and Ergonomics:

-

Weight and Balance: A lightweight drill reduces fatigue, especially for overhead or prolonged use.

-

Handle Design: Look for models with rubberized grips and adjustable side handles for better control and reduced strain.

-

Vibration Control: Advanced models include features to minimize vibration for added comfort during extended use.

7. Durability and Build Quality:

-

Material: Opt for drills with rugged housings, typically metal or reinforced plastic, for long-term reliability.

-

Overload Protection: Prevents motor damage during intensive use.

8. Features and Accessories:

-

LED Worklight: Helps illuminate dark work areas for precise drilling.

-

Depth Stop Rod: Ensures consistent hole depth for tasks requiring precision.

-

Dust Collection System: Reduces cleanup and improves safety in dusty environments.

9. Brand Reputation and Warranty:

-

Choose brands known for reliability and quality, such as DeWalt, Bosch, Makita, or Milwaukee.

-

Check the warranty for coverage on defects or motor performance.

10. Budget and Intended Use:

-

DIY or Occasional Use: A mid-range hammer drill should suffice for light to moderate tasks.

-

Professional or Heavy-Duty Use: Invest in a high-performance model with advanced features.

By evaluating these factors, you can select a hammer drill that matches your project requirements, enhances efficiency, and provides long-term value.

Frequently Asked Questions (FAQ)

1. What is a hammer drill used for?

A hammer drill is used for drilling into hard materials such as concrete, brick, and stone. It’s ideal for tasks like installing anchors, drilling holes in masonry, or mounting fixtures on tough surfaces.

2. How is a hammer drill different from a regular drill?

A hammer drill combines rotary drilling with a percussive hammering action, allowing it to break through hard materials. Regular drills only use rotary motion, making them less effective on masonry or concrete.

3. Can a hammer drill be used on wood or metal?

Yes, most hammer drills have a drill-only mode that can be used for wood, metal, and other softer materials. However, switching off the hammering action is necessary for these materials.

4. What is the difference between a hammer drill and a rotary hammer?

While both tools use hammering action, a rotary hammer is more powerful, with pneumatic hammering mechanisms for heavy-duty tasks. Hammer drills are more versatile and suitable for lighter masonry work.

5. Do I need a corded or cordless hammer drill?

- Corded Hammer Drills: Offer consistent power, ideal for heavy-duty or long-duration tasks.

- Cordless Hammer Drills: Provide mobility and convenience, perfect for quick or remote jobs.

6. What type of drill bits should I use with a hammer drill?

Use masonry drill bits with carbide or diamond tips for concrete, brick, or stone. Ensure the bit size matches the chuck and project requirements.

7. Can a hammer drill be used for chiseling?

Most hammer drills are not designed for chiseling. However, rotary hammers with a “hammer-only” mode can perform chiseling tasks like breaking tiles or concrete.

8. How do I maintain a hammer drill?

- Clean the drill and chuck after each use.

- Inspect the power cord or battery regularly for damage.

- Lubricate moving parts if recommended by the manufacturer.

- Store in a dry, safe location.

9. Is a hammer drill safe to use?

Yes, when proper precautions are taken. Always wear safety gear like goggles, gloves, and a dust mask. Use both hands for better control and avoid loose clothing that could get caught.

10. How much does a hammer drill cost?

Hammer drill prices vary based on features and brand:

- Basic Models: $50–$100.

- Mid-Range Models: $100–$200.

- Professional Models: $200–$500 or more.

11. Do I need a hammer drill for DIY projects?

If your projects involve drilling into masonry, concrete, or stone, a hammer drill is essential. For general home improvement tasks on softer materials, a standard drill may suffice.

12. Can I use a hammer drill for demolition?

Light demolition tasks, such as removing small sections of concrete or brick, may be possible with a hammer drill. For more extensive demolition, a rotary hammer is recommended.

13. Are there specific safety tips for using a hammer drill?

Yes, key safety tips include:

- Use both hands for control.

- Wear appropriate PPE (goggles, gloves, dust mask).

- Avoid drilling into hidden wires or pipes by checking the area first.

ToolFinder Recommends

Hammer drills are a highly personal choice, with each user having unique preferences and needs. When selecting a hammer drill, it’s essential to choose a model that aligns with your specific goals, whether you’re tackling DIY home improvement projects, masonry work, or professional construction tasks. While sticking to a single brand for compatibility with accessories or batteries can be advantageous, it’s perfectly fine to mix and match brands if that suits your needs better.

Another key consideration is power source. Corded hammer drills are ideal for heavy-duty or prolonged use, offering consistent power for demanding tasks like drilling into concrete or masonry. Cordless hammer drills, on the other hand, provide portability and convenience, making them a great choice for quick jobs or work in remote areas. Balancing your need for power, mobility, and task-specific features will help you select a hammer drill that’s effective and tailored to your unique projects.

Dewalt DCD799L1 20V MAX ATOMIC COMPACT SERIES Brushless Lithium-Ion 1/2 in. Cordless Hammer Drill Kit (3 Ah)

Selection of Hammer Drill is pretty specific to your needs an application, but this DeWalt unit is great for portability and if you already have DeWalt 20V Tools, works on the same batteries as their similar line: Dewalt DCD799L1 20V MAX ATOMIC COMPACT SERIES Brushless Lithium-Ion 1/2 in. Cordless Hammer Drill Kit (3 Ah)

Milwaukee Electric Tools 2804-22 Hammer Drill Kit (18V)

Selection of Hammer Drill is pretty specific to your needs an application, but this Milwaukee unit is great for portability and if you already have Milwaukee 18V Tools, works on the same batteries as their similar line. Another bonus with this unit is inclusion of a side handle and case: Milwaukee Electric Tools 2804-22 Hammer Drill Kit

Recommended Accessory Kits

48-20-9058 for Milwaukee 10Pc. Shockwave Impact Duty Carbide Hammer Drill Bit Kit

Looking for a set with a nice case and easy storage? This set will offer a variety of carbide bits for everyday use. : 48-20-9058 for Milwaukee 10Pc. Shockwave Impact Duty Carbide Hammer Drill Bit Kit

What about when you need extra long bits?

Extension Concrete Drill Bit Lengthening 1pcs 3/8" X 39" Cross-Type Double Thread Carbide Material Suitable For Concrete, Brick, Cement Walls, Stone, extra long Hammer Drill Bits For Concrete

These bits are available in multiple sizes, but this common size of 3/8″ has multiple options on the page. : Extension Concrete Drill Bit Lengthening 1pcs 3/8″ X 39″ Cross-Type Double Thread Carbide Material Suitable For Concrete, Brick, Cement Walls, Stone, extra long Hammer Drill Bits For Concrete