Infrared Thermometer

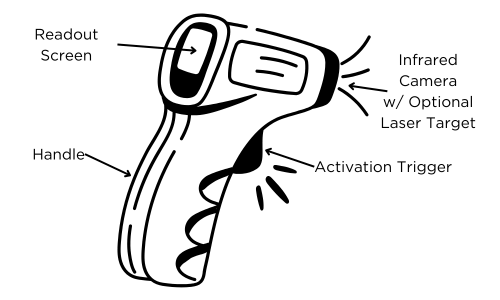

Anatomy of an Infrared Thermometer

What is an Infrared Thermometer?

Who would use an Infrared Thermometer?

Infrared Thermometers are widely used by professionals and hobbyists across a variety of fields for quick, accurate temperature readings without contact. Here’s who would benefit from using an IR thermometer:

- HVAC Technicians: For measuring air and surface temperatures of ducts, vents, and equipment to diagnose efficiency issues and detect temperature variations.

- Automotive Technicians: To check the temperature of engine components, brakes, and exhaust systems, helping identify issues or monitor performance without direct contact.

- Electricians and Electronics Technicians: Used to monitor temperatures of circuit boards, batteries, transformers, and other sensitive components to prevent overheating and ensure safe operation.

- 3D Printing Enthusiasts: For confirming print bed and extruder temperatures, helping ensure optimal conditions for filament adhesion and print quality.

- Metalworkers and Fabricators: To monitor the temperature of metal surfaces during welding, bending, or tempering processes, ensuring materials are treated safely and effectively.

- Chefs and Food Safety Inspectors: For checking the surface temperature of foods without contamination, particularly useful in commercial kitchens for quick food safety checks.

- Home Inspectors and DIY Hobbyists: For detecting hot or cold spots in walls, floors, or ceilings, helping identify insulation issues or potential leaks.

- Plumbers: To quickly assess pipe temperatures, locate hot water lines, and identify potential temperature-related issues without needing to touch the pipes directly.

- Model Makers and Artists: For monitoring temperatures when working with temperature-sensitive materials like resin, wax, or plastic, ensuring consistency in crafting and finishing processes.

- Flooring Installers: To confirm the temperatures of adhesives and flooring materials for proper curing and installation, which is essential in specific flooring types like vinyl or laminate.

Infrared thermometers are valued in these fields for their accuracy, efficiency, and safety, making it easy to measure surface temperatures without contact, even in hard-to-reach or hazardous areas.

Safety Precautions with Infrared Thermometers?

Infrared Thermometers are generally safe to use, but here are some key safety precautions to keep in mind:

- Avoid Direct Eye Exposure to Lasers: Many infrared thermometers include a laser pointer to help target specific areas. Always avoid pointing the laser at anyone’s eyes or at reflective surfaces that could redirect the laser, as it may cause eye injury.

- Use Certified Models for Precision Tasks: For applications requiring high accuracy, such as scientific measurements or medical uses, only use models certified for those purposes. Non-certified units may lack the precision needed for critical readings, potentially leading to incorrect results.

- Mind Surface Emissivity Settings: To ensure accurate readings, adjust the emissivity setting based on the surface material. Using an incorrect setting can lead to inaccurate temperature readings, which is important for applications where precise temperatures are required.

- Don’t Use on Humans or Animals: Unless specifically designed for medical use, IR thermometers are not calibrated for measuring human or animal body temperature. Using a non-medical IR thermometer in this way can give inaccurate readings.

- Be Aware of Reflective Surfaces: Reflective materials, such as metals, can distort temperature readings. Avoid using IR thermometers on these surfaces unless the device allows for emissivity adjustment, or place a piece of masking tape on the surface to read from instead.

- Store Safely: When not in use, keep the thermometer in a protective case or in a location where the lens and sensor won’t get scratched or dirty, as this can impact accuracy over time.

- Check for Environmental Interference: External factors like dust, steam, or smoke can affect the accuracy of readings. When working in such environments, keep the line of sight between the IR thermometer and the target clear for best results.

These precautions ensure accurate, safe, and effective use of infrared thermometers, helping users obtain reliable readings across a variety of applications.

Considerations in Choice of Infrared Thermometer

When selecting an Infrared Thermometer, consider the following factors to ensure it meets your needs:

- Temperature Range: Choose a thermometer with a range suitable for your applications. For example, general-use IR thermometers often max out around 400°F (200°C), while industrial models can go up to 1000°F (540°C) or higher, useful for automotive, metalworking, and other high-temperature applications.

- Accuracy and Precision: Look for a model with a high accuracy rating, especially if you’ll be using it for sensitive measurements. For general tasks, an accuracy of ±2% is typical, while some advanced models offer greater precision for critical applications.

- Distance-to-Spot Ratio (D): This ratio determines the area being measured relative to the distance from the target. Higher ratios, like 12:1 or 16:1, allow for precise readings from farther away, making them ideal for smaller targets or situations where close contact isn’t possible.

- Emissivity Adjustment: Emissivity settings let you calibrate the thermometer based on different materials, improving accuracy on surfaces like metal, wood, or plastic. Models with adjustable emissivity are more versatile, especially for industrial or multi-material use.

- Laser Targeting: A built-in laser pointer helps pinpoint the exact area being measured, which is particularly useful when working with small or distant targets. Some models offer dual lasers to outline the area for an even more precise reading.

- Response Time: Faster response times (often within milliseconds) provide quick readings, beneficial for tasks that require rapid or frequent measurements.

- Display Features: Look for models with large, backlit displays, especially if you’ll be working in dim or bright lighting. Some displays also show minimum, maximum, and average temperatures, which can be helpful for monitoring over time.

- Battery Life and Power Source: Choose a model with a reliable power source and battery life, especially if you’re using it for extended periods. Some thermometers offer power-saving modes or rechargeable battery options for convenience.

- Data Logging and Connectivity: Advanced IR thermometers may feature data logging capabilities or Bluetooth/Wi-Fi connectivity, allowing you to store readings or sync data to devices for tracking and analysis, which is ideal for professional or industrial use.

- Build Quality and Durability: Industrial models often have rugged designs with impact-resistant or waterproof features to withstand harsh environments. If you’re using the thermometer in tough settings, choose a durable model designed for heavy use.

By considering these features, you can select an infrared thermometer that provides reliable, accurate, and easy-to-read temperature measurements tailored to your specific needs.

How does an Infrared Thermometer compare to other types?

Here’s a comparison between infrared thermometers and other common thermometer types used in trades, highlighting the unique benefits and limitations of each:

- Infrared Thermometers (IR Thermometers)

- Function: Measures surface temperature without direct contact by detecting infrared radiation.

- Best For: Situations where quick, non-contact readings are needed, such as checking HVAC ducts, automotive parts, electrical components, or 3D print beds.

- Advantages: Fast, safe for high-temperature or hard-to-reach surfaces, minimal risk of contamination.

- Limitations: Cannot measure internal temperatures; readings may be affected by surface reflectivity if not calibrated.

- Digital Probe Thermometers

- Function: Uses a metal probe to measure internal temperatures by direct contact.

- Best For: Measuring internal or core temperatures in HVAC systems, liquids, or food safety applications.

- Advantages: Accurate for internal readings, often with a wide temperature range, easy-to-read digital display.

- Limitations: Requires direct contact with the surface or material, which can be slow for multi-point measurements; not ideal for extremely hot or hazardous surfaces.

- Thermocouple Thermometers

- Function: Measures temperature using a thermocouple sensor with two dissimilar metals that produce voltage in response to heat.

- Best For: Industrial applications, including HVAC, kilns, and furnaces, where highly precise readings are required over a wide temperature range.

- Advantages: Very high accuracy, wide range, suitable for both surface and internal measurements.

- Limitations: More expensive, requires compatible probes, and usually involves setup time; probe can be delicate in some models.

- Dial Thermometers (Analog Thermometers)

- Function: Analog thermometers with a dial and metal probe that give a temperature reading based on expansion of the material inside the probe.

- Best For: Simple, low-precision measurements in environments where digital or infrared thermometers are not ideal, like ovens or HVAC systems.

- Advantages: No batteries needed, durable, good for checking temperature changes over longer periods.

- Limitations: Slower response time, lower accuracy, and can be difficult to read precisely; requires direct contact.

- Bimetallic Strip Thermometers

- Function: Uses a strip made of two different metals that expand at different rates with temperature changes to move a needle on a dial.

- Best For: Industrial settings like refrigeration or air-conditioning where ambient or environmental temperature readings are required.

- Advantages: Durable, often used in fixed installations, does not require batteries.

- Limitations: Not suitable for precise temperature readings; typically not portable.

Infrared Thermometers stand out for non-contact, instant surface temperature readings, ideal for quick diagnostics in high-heat, hard-to-reach, or hazardous areas. Other types, like digital probes and thermocouples, excel in applications requiring precise internal or surface measurements through direct contact, often at the cost of speed or ease of use. Selecting the best thermometer depends on the environment, required accuracy, and specific application needs.

Frequently Asked Questions (FAQ)

1. What is an infrared thermometer, and how does it work?

An infrared thermometer measures the surface temperature of an object without contact by detecting the infrared radiation emitted. The device converts this radiation into a temperature reading, making it ideal for situations where quick, non-contact measurements are needed.

2. Can an infrared thermometer measure internal temperatures?

No, infrared thermometers are only designed to measure surface temperatures. They are not suitable for internal measurements in materials like food, liquids, or other dense objects. Use a probe or thermocouple thermometer for internal temperature readings.

3. How accurate are infrared thermometers?

Accuracy depends on the model and settings. High-quality IR thermometers can be accurate within ±1-2% of the actual temperature. Using emissivity settings correctly and ensuring the correct distance-to-spot ratio improves accuracy.

4. What is the distance-to-spot ratio, and why does it matter?

The distance-to-spot (D) ratio determines the area measured by the IR thermometer based on distance. For example, a 12:1 ratio means the thermometer will measure a 1-inch area from 12 inches away. A higher ratio allows for more accurate readings from greater distances.

5. Can I use an infrared thermometer to check body temperature?

Unless specifically designed and certified for medical use, standard IR thermometers are not recommended for measuring body temperature. Non-medical IR thermometers lack the necessary calibration for accurate human temperature readings.

6. Why are there adjustable emissivity settings?

Emissivity settings adjust for the material being measured, as different surfaces emit infrared radiation differently. Materials like metals, plastics, and ceramics require specific emissivity adjustments to achieve accurate readings.

7. Are IR thermometers affected by environmental factors?

Yes, factors like steam, dust, and smoke can interfere with the infrared sensor, leading to inaccurate readings. Clear any obstructions between the thermometer and the target surface for the best results.

8. Can an infrared thermometer measure air temperature?

No, IR thermometers measure surface temperatures only. They are not suitable for measuring the temperature of gases or the air. Use a digital thermometer with an ambient sensor for air temperature readings.

9. How do I know if I’m getting an accurate reading?

To improve accuracy, ensure the emissivity is correctly set, keep a clear line of sight to the target surface, and maintain the appropriate distance for your model’s D ratio. For surfaces with high reflectivity, cover the area with non-reflective tape, allow it to reach the surface temperature, and then measure.

10. What maintenance is required for an infrared thermometer?

To maintain accuracy, keep the lens clean and free of dust or debris, avoid dropping the device, and store it in a protective case. Regularly check batteries and replace them as needed for optimal performance.

ToolFinder Recommends

Etekcity Infrared Thermometer Temperature Gun 1080, -58°F to 1130°F for Meat Food Pizza Oven Griddle Accessories, Heat Gun for Cooking, Kitchen, Fridge, Reptile,BBQ

For a general purpose Infrared Thermometer that can be used for common DIY tasks, check out this model from Etekcity : Etekcity Infrared Thermometer Temperature Gun 1080, -58°F to 1130°F for Meat Food Pizza Oven Griddle Accessories, Heat Gun for Cooking, Kitchen, Fridge, Reptile,BBQ

Fluke 62 Max Industrial Infrared Thermometer, -22 to +932 Degree F Range, Single Laser Targeting, 10:1 Distance To Spot Ratio, IP54 Rating, Includes 3 Year Warranty, (Not For Human Temp)

Have a need for an industrial-grade NIST Certified Infrared Thermometer? This Fluke series is likely to have a unit to fit the bill. Check out this one : Fluke 62 Max Industrial Infrared Thermometer, -22 to +932 Degree F Range, Single Laser Targeting, 10:1 Distance To Spot Ratio, IP54 Rating, Includes 3 Year Warranty, (Not For Human Temp)