Calipers (Digital)

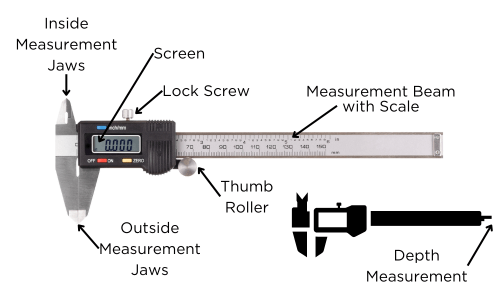

Anatomy of a Digital Caliper

What is a Digital Caliper?

Who would use a Digital Caliper?

Digital Calipers are widely used by:

- Engineers and Machinists: For precise measurements of parts and components to ensure they meet design specifications.

- Woodworkers and Carpenters: To measure wood thickness, spacing, and internal dimensions, especially when creating intricate joinery.

- Metalworkers and Fabricators: To check metal thickness and diameters, ensuring precision in cuts, bends, and welds.

- 3D Printing Enthusiasts: For measuring filament diameter and verifying printed parts match design dimensions.

- Jewelry Makers: To measure small components and gemstones accurately, crucial in detailed and delicate work.

- DIY Hobbyists: For various home projects requiring accurate measurements, like installing fixtures or crafting items.

- Automotive Technicians: For measuring brake rotors, engine components, and other critical parts needing exact specifications.

- Model Makers: To achieve precise measurements on small-scale items, from miniatures to architectural models.

Safety Precautions with Calipers aren't really a concern but:

Safety precautions with calipers are minimal, but proper handling and care are essential to ensure accurate measurements and prolong tool life. Here are some best practices:

- Avoid Dropping: Calipers are precision instruments; dropping them can affect accuracy. Always handle them with care and avoid placing them on the edge of a workbench.

- Keep Clean and Free of Debris: Dust, metal shavings, or other debris can get into the caliper’s sliding mechanism, causing inaccurate readings. Wipe them down after each use, especially if used in dusty environments.

- Store Properly: When not in use, keep calipers in their protective case to avoid damage and exposure to moisture, which can lead to rust.

- Avoid Excessive Force: Don’t apply too much pressure when measuring, as it can cause inaccurate readings and wear down the jaws over time.

- Regular Calibration Checks: Periodically check calibration, especially if using calipers for precision work, to ensure ongoing accuracy.

Following these practices keeps digital calipers in peak condition, providing reliable and accurate measurements for years.

Considerations in Choice of Digital Calipers

Here are some key considerations when choosing digital calipers:

- Measurement Range: Standard calipers usually measure up to 6 inches (150 mm), but larger ranges are available. Choose a range suited to your projects’ typical dimensions.

- Accuracy and Resolution: Look for high accuracy (e.g., ±0.001 inches or ±0.02 mm) for precision work, and ensure the resolution meets your needs, especially in fields requiring very fine measurements.

- Build Material: Stainless steel calipers are durable and resistant to corrosion, making them ideal for long-term, reliable use. Plastic calipers are lightweight and budget-friendly but may lack durability.

- Ease of Reading: Large, high-contrast LCD screens improve readability, especially if you’ll use the tool frequently or in various lighting conditions.

- Battery Life and Auto-Off Feature: Frequent users should opt for calipers with extended battery life and an auto-off function to conserve power.

- Water and Dust Resistance: For use in tough environments, consider models with IP54 or higher ratings, which provide protection against dust and light water exposure.

- Metric and Imperial Conversion: If you work with both metric and imperial measurements, look for calipers with quick-switch conversion functionality.

- Price and Brand Reliability: Reputable brands often provide better accuracy and durability. Balancing cost with brand reliability ensures you get a quality instrument within your budget.

By considering these factors, you can select digital calipers that are well-suited to your specific needs and ensure they perform reliably over time.

Digital vs Dial vs Manual Calipers

Here’s a comparison of Digital, Dial, and Manual Calipers to help users choose the best option for their needs:

Frequently Asked Questions (FAQ)

1. What can I measure with digital calipers?

Digital calipers can measure the external dimensions, internal dimensions, and depth of objects. They’re commonly used for precise measurements of thickness, diameter, and spacing in fields like woodworking, metalworking, and 3D printing.

2. How accurate are digital calipers?

Most digital calipers offer accuracy within ±0.001 inches (0.02 mm), making them highly precise for detailed work. However, accuracy may vary depending on the brand and model, so it’s essential to check specifications.

3. Do digital calipers need calibration?

Yes, regular calibration is recommended, especially for high-precision work. Calibrate them periodically or whenever you notice potential inaccuracies.

4. Are digital calipers waterproof?

Some digital calipers come with IP ratings (like IP54) that offer limited water and dust resistance. Check the product specifications if you’ll be using calipers in damp or dusty environments.

5. How do I change units on digital calipers?

Most digital calipers have a unit conversion button that allows you to toggle between metric (mm) and imperial (inches) measurements easily.

6. How long do batteries last in digital calipers?

Battery life varies, but many digital calipers have auto-off features to help conserve power, typically lasting several months with regular use.

7. What’s the difference between digital, dial, and manual calipers?

Digital calipers offer quick, easy readings on an LCD screen; dial calipers have a mechanical dial for readings; and manual (Vernier) calipers require reading a scale. Digital calipers are generally faster and easier to use.

8. How do I care for my digital calipers?

To prolong their life, clean the jaws after each use, avoid exposure to moisture (unless they’re water-resistant), and store them in a protective case. Handle with care to prevent drops or impacts that could affect accuracy.

9. What size digital caliper should I buy?

Standard digital calipers measure up to 6 inches (150 mm), which suits most projects. For larger or specialized work, longer options (8-12 inches) are available.

10. Can digital calipers be used for 3D printing?

Yes, digital calipers are ideal for 3D printing. They’re used to check filament diameter, verify part dimensions, and help with calibration, ensuring your prints are accurate.

ToolFinder Recommends

Digital Caliper, 6 Inch Caliper Tool with Extra Large LCD Screen, Auto-Off Feature, Easy Switch from Inch Metric Fraction

It’s hard to recommend digital calipers without knowing what stage someone might be at in their journey. If you’re just looking for a set that should hold up to some hobby use at a reasonable price, check out this set: Digital Caliper, 6 Inch Caliper Tool with Extra Large LCD Screen, Auto-Off Feature, Easy Switch from Inch Metric Fraction, Stainless Steel Vernier Caliper Measuring Tool for DIY/Household

Mitutoyo 500-196-30 Advanced Onsite Sensor (AOS) Absolute Scale Digital Caliper, 0 to 6"/0 to 150mm Measuring Range, 0.0005"/0.01mm Resolution, LCD

When precision is of the utmost importance, a trusted, tried and true Mitutoyo could be a great choice. Check out this 6″ set: Mitutoyo 500-196-30 Advanced Onsite Sensor (AOS) Absolute Scale Digital Caliper, 0 to 6″/0 to 150mm Measuring Range, 0.0005″/0.01mm Resolution, LCD

NEIKO 01409A 12” Electronic Digital Caliper | Extra Large Display | 0-12 Inches | Inch/Fractions/Millimeter Conversion | Polished Stainless Steel

If you need a longer caliper to keep at the ready, Neiko’s Stainless Digital Caliper could be a good fit. Check out this 12″ set: NEIKO 01409A 12” Electronic Digital Caliper | Extra Large Display | 0-12 Inches | Inch/Fractions/Millimeter Conversion | Polished Stainless Steel